KEY INNOVATION PROJECTS

KEY INNOVATION PROJECTS

Translating advanced material innovation and circularity into measurable commercial success and significant industry impact.

Scaled Circular Innovation:

Mono-Material Solutions for a Diverse Product Ecosystem

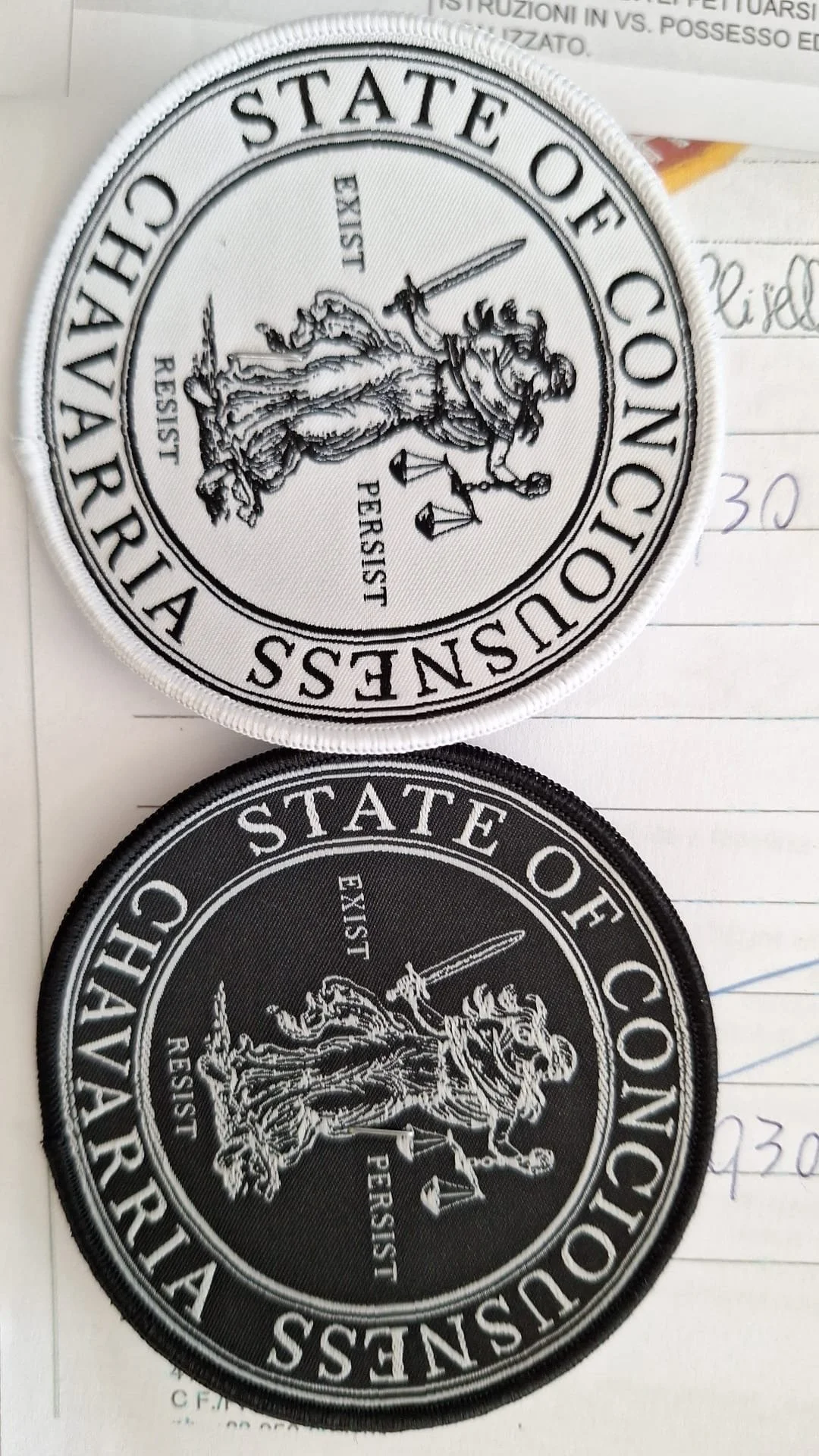

We’re honored to be part of @willychavarrianewyork latest collection. Eight brand new items, made from 100% RTV Material, available now. Circularity never looked so good.

Dream it.

The Vision: To develop an entire collection of disparate products—including swimwear, headwear, and eyewear frames—each engineered solely from recycled Nylon 6, guaranteeing complete circularity from manufacturing to end-of-life. The challenge was immense: adapting one polymer to vastly different functional requirements (e.g., rigid eyewear frames, soft swimwear, structured hats with multiple layers) while ensuring performance, aesthetics, and full recyclability.

The Objective: Lead the comprehensive development and commercialization of this multi-product mono-material collection, proving the versatility and scalability of a single-polymer circular economy across diverse apparel and accessory categories.

Build it.

Strategic Leadership: Directed a cross-functional team through the intricate process of material formulation, product design, and manufacturing integration for a complex, multi-product line.

Advanced Material Engineering: Leveraging unparalleled knowledge of Nylon 6 polymer science, textile chemistry, and manufacturing processes, I spearheaded the adaptation of this mono-material for each unique product and its components:

Swim Trunks: Innovated bespoke Nylon 6 formulations for main body fabric, stretchable rib knit waistband, durable drawcords, breathable mesh lining, branding labels (main and care), and high-performance sewing thread, ensuring chlorine resistance and quick-dry properties.

Hat: Developed specialized Nylon 6 for the main body fabric, rigid brim, functional button, absorbent sweatband fabric, branding labels (main and care), internal binding, and fusible interlinings, maintaining structure and comfort.

Sunglasses (Frame Only): Guided the material science for injection-molded Nylon 6 frames, ensuring optimal rigidity, surface finish, and skin compatibility.

Holistic Technical Development: Established rigorous, category-specific testing protocols for performance, durability, and recycling compatibility, validating each product's mono-material integrity. This included optimizing dye chemistry and print formulations to ensure colorfastness and vibrancy, all within the Nylon 6 system.

Integrated Supply Chain: Orchestrated the engagement and development of a specialized preferred supplier network capable of handling diverse manufacturing processes—from injection molding for frames to various knitting/weaving for fabrics, and specialized trim production—all within the strict mono-material framework.

Grow it.

Market Launch: Successfully brought to market a pioneering collection of 100% recycled and fully recyclable mono-material products, setting a new industry standard for versatile and systemic circular design.

Quantifiable Environmental Impact: This comprehensive collection delivered significant environmental benefits, demonstrating the power of scaled circular material innovation:

Achieved an average of 87.2% reduction in CO2e emissions across the collection compared to using virgin Nylon 6.

Specific CO2e Savings per kg of Recycled Nylon 6:

Standard Virgin Nylon 6 (Ecoinvent LCA): 8.6 kg CO2e/kg

Higgs MSI Index (Virgin Nylon 6): 6.9 kg CO2e/kg

RTV Recycled Nylon 6 (Our Mono-Material): 0.7 kg CO2e/kg

Commercial Success: Secured predictable market uptake through strategic off-take agreements, validating the commercial viability of multi-product mono-material collections and opening new revenue streams.

Future Foundation: This project served as a critical proof-of-concept for applying holistic circular design principles across diverse product categories, paving the way for wider industry adoption of truly regenerative material systems.

Circular Mono-Material Tote

@anybagproject X @return_to_vendor

♻️ 🌎 🗓️ Earth Day drop 💧 ☀️ 🌱

Dream it.

The Vision: To develop a truly circular, high-performance tote bag where every single component (webbing straps, quilting, embroidery, edge finishes) is mono-material Nylon 6, ensuring ultimate end-of-life recyclability.

The Objective: Lead the development and commercialization of a mono-material solution for a multi-component tote, proving that complex items can be seamlessly returned to the material stream.

Build it.

Strategic Leadership: Spearheaded the development process, from conceptualization to market readiness, overseeing all aspects of material science and product engineering for a multi-component system.

Mono-Material Engineering: Leveraging deep knowledge of textile chemistry and polymer composition, I led the refinement of our advanced mono-material technology (recycled Nylon 6). This involved optimizing specific extrusion processes and formulations for distinct components:

Quilted Body: Developing specific yarn structures and weaving patterns for the main fabric and interior batting.

Webbing & Edge Finishes: Formulated Nylon 6 for high-tensile strength and abrasion resistance.

Embroidery Thread: Innovating fine-gauge Nylon 6 threads capable of computer & machine embroidery.

Grow it.

Market Launch: Successfully launched the industry's first-of-its-kind 100% recycled and fully recyclable mono-material tote bag, setting a new benchmark for sustainable accessories that are truly 'design for disassembly and recycling.'

Quantifiable Environmental Impact: This innovation delivered profound environmental benefits, demonstrating the tangible power of circular materials:

Achieved an 87.2% reduction in CO2e emissions compared to using virgin Nylon 6.

Specific CO2e Savings per kg:

Standard Virgin Nylon 6 (Ecoinvent LCA): 8.6 kg CO2e/kg

Higgs MSI Index (Virgin Nylon 6): 6.9 kg CO2e/kg

RTV Recycled Nylon 6 (Our Mono-Material): 0.7 kg CO2e/kg

Commercial Success: Ensured predictable market uptake through strategic off-take agreements and commercial contracts, translating environmental leadership into tangible revenue growth and solidifying a competitive advantage in the sustainable accessories market.

Supply Chain Integration: Developed a robust internal framework and engaged a preferred supplier network across raw material and manufacturing tiers, ensuring seamless integration of this novel mono-material into diversified production lines for specialized components.

Future Foundation: This project established a scalable blueprint for future mono-material innovations, proving that high-performance circular design for multi-component items is not only achievable but also economically and environmentally superior.